Lab measurements equipment is highly accurate, but based on sampling a selection of the entire production.

The 360° Can Inspection module is a highly accurate, reliable and proven Mix-Up & Integrity Detection system for lithographed & labeled cans. The system integrates multiple functions hybridly in one system

The Semi-Automatic Combination Seam Gauge provides automated seam thickness and countersink depth measurements, including the option of a 360° scan of seam thickness.

The new 3rd Generation XTS is a stand-alone measurement system that provides non-destructive, double seam inspection for round cans (aluminum or steel).

The Dome Reversal Tester is a semi-automated buckle tester designed to determine the pressure at which the bottom dome of a finished beverage can begins to buckle.

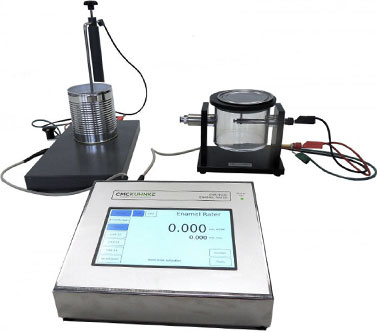

The ENR-4000?Digital Enamel Rater?is a complete redesign of the industry leading CMC KUHNKE Enamel Rater. It tests the coverage of the enamel coating inside food and beverage cans and ends and it? accurately and quickly measures the Enamel Rating and Lacquer Permeability.